A well-functioning line consists of many, often “invisible” components that play an irreplaceable part in its productivity. For us, ti´s customary to include those accessories in our designs from the very beginning of the process. They facilitate operation, ensure safety and, last but not least, the functionality of the entire automation.

In case we are asked for additions or modifications to existing line, we are designing custom made solutions.

Accessories for better functionality

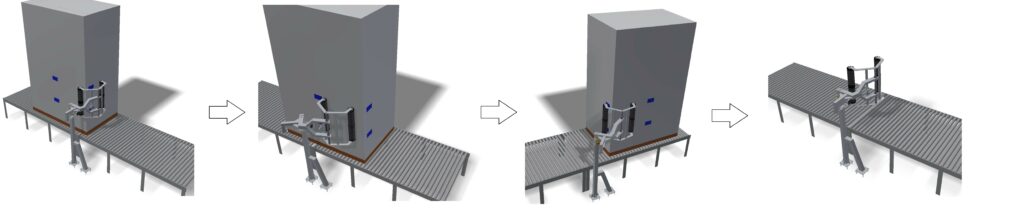

Automatic centering device for pallets

Centering device is guiding pallet or base board to the middle of conveyor before loaded with products.

To achieve better results, we changed the pneumatically controlled centering devices for new, which are controlled by electric transmission

Mechanical pressing of the labels

The mechanism always starts it´s pressing cycle in the starting position. The pressing device is activated by arriving stack moving along the conveyor.

Pressing of the label is ensured by rotating rollers with a soft rubber surface that absorbs possible unevenness on the surface.

Once the pressing operation is complete, the mechanism returns to its original starting position and get´s ready for the arrival of next pile to repeat the work cycle.

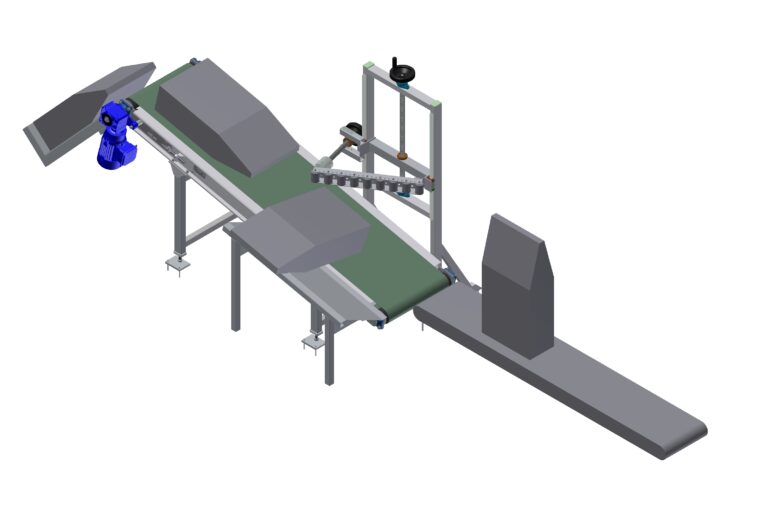

Mechanical inclined drop

The direction of material flow must be set the way, it connects smoothly to upcoming operations on the line. Installation of the mechanical inclined drop ensures fluent transport of material in the desired position towards the output conveyor, without any further manual interference from the operators.